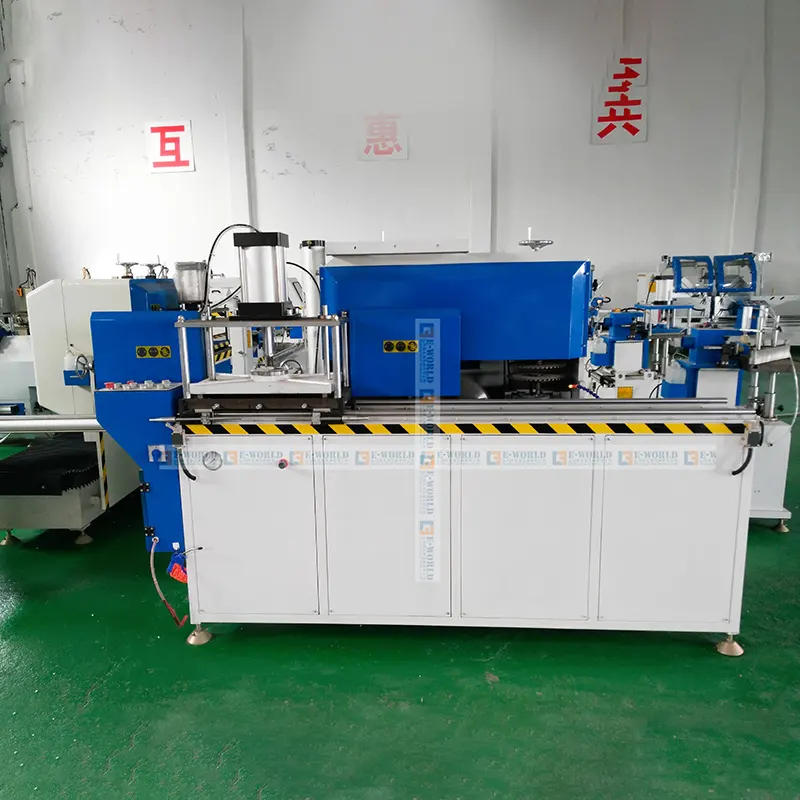

High-quality Aluminium Punching Machine for Sliding Windows & Doors Price List

Product Overview

- The product is a high-quality Aluminium Punching Machine for Sliding Windows & Doors designed for end milling of profiles for aluminum doors and windows.

- It features a large-sized work bench, long cutting feed travel, and adjustable multiple cutting tools.

- The machine is able to mill 6-10 profiles in one operation without the need to replace cutting tools, saving production setup time and tool costs.

Product Features

- Multiple sets of cutting tools can work simultaneously or separately based on different profiles.

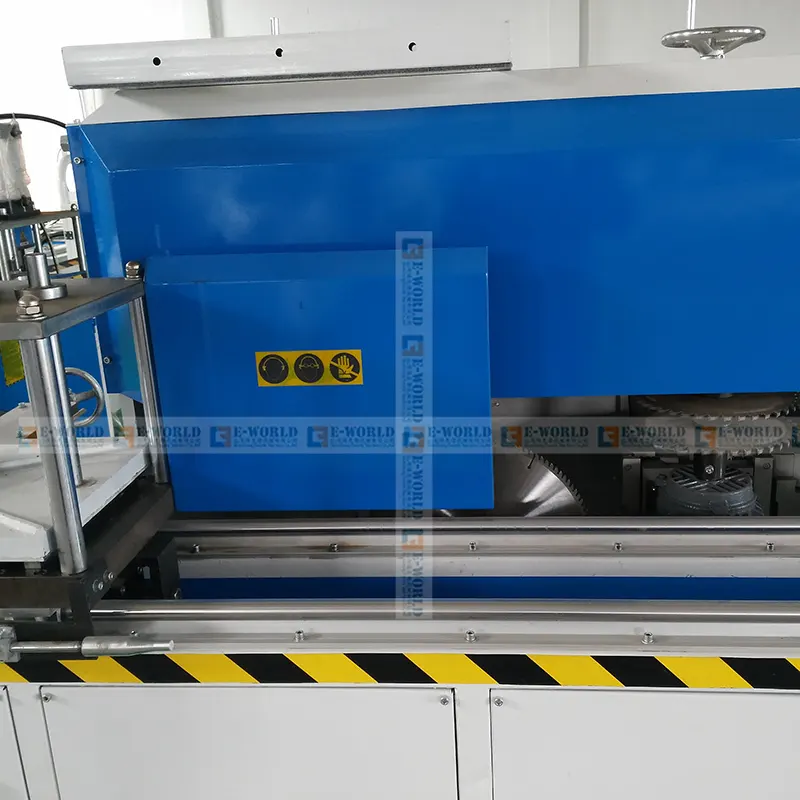

- With a bigger diameter of cutting tools and the use of hydraulic damping cylinder, it ensures better machining surface quality and stability during operations.

- The thickened clamping plate prevents profiles from deforming.

Product Value

- The product offers efficient and cost-effective end-milling solutions for aluminum doors and windows manufacturing.

- It provides stable performance and meets customer demands with the latest industry developments.

- The machine is designed for high efficiency, low production cost, and short lead time.

Product Advantages

- Adjustable multiple cutting tools and simultaneous/ separate operation options for different profiles.

- Better machining surface quality and stability during operations with a bigger diameter of cutting tools and hydraulic damping cylinder.

- The thickened clamping plate prevents profiles from deforming.

Application Scenarios

- The Aluminium Punching Machine for Sliding Windows & Doors is ideal for use in manufacturing aluminium doors and windows.

- It is suitable for end milling profiles with precision and efficiency for various applications in the construction industry.

- The machine offers value in saving production setup time and tool costs, making it a versatile solution for door and window manufacturers.