The Evolution Of Glass Machine Technology: From Hand-blown To Automated Production

Glass has been an essential material for thousands of years, and the evolution of glass machine technology has played a crucial role in its production. From the labor-intensive process of hand-blowing glass to the efficiency of automated production, the advancements in technology have revolutionized the way we create and utilize this versatile material. Join us as we explore the fascinating journey of glass machine technology and the impact it has had on the manufacturing industry. Whether you're a glass enthusiast or simply curious about the evolution of technology, this article will provide valuable insights into this enduring art form.

- The Origins of Hand-Blown Glass Production

The origins of hand-blown glass production date back to the ancient world, with evidence of early forms of glassblowing found in Mesopotamia and Egypt around 1500 BC. This early method of glass production involved skilled artisans blowing air into a molten blob of glass to create a variety of objects, such as vessels, beads, and decorative items.

The art of hand-blown glass production spread throughout the Roman Empire, where it reached its peak in the 1st century AD. Skilled glassblowers created intricate designs and shapes, including bottles, bowls, and ornamental pieces, using methods that have remained largely unchanged for centuries.

The process of hand-blown glass production involves gathering molten glass on the end of a hollow tube, then blowing and shaping the glass into its desired form. This method requires a high level of skill and precision, as the glassblower must carefully control the temperature and shape of the glass to create the desired object.

Hand-blown glass production continued to be the primary method of glassmaking for centuries, with only minor advancements in technique and equipment. However, the industrial revolution brought significant changes to the world of glass production, including the introduction of the first mechanical glassblowing machines.

These early glass machines automated the process of gathering, shaping, and blowing glass, allowing for faster and more consistent production of glass objects. While these machines revolutionized the industry, hand-blown glass production remained an important part of the craft, as it continued to be used for creating unique and artistic pieces.

As technology continued to advance, so did the capabilities of glass machines. The development of new materials and techniques allowed for the creation of more complex and intricate glass objects, paving the way for the modern glass industry.

Today, hand-blown glass production remains an important part of the glassmaking tradition, with skilled artisans continuing to create beautiful and unique pieces using traditional methods. However, the majority of glass production has shifted to automated processes, with advanced glass machines capable of producing a wide range of products with speed and precision.

The evolution of glass machine technology has transformed the industry, making glass production more efficient and accessible than ever before. While hand-blown glass production will always hold a special place in the world of glassmaking, the advancements in glass machine technology have opened up new possibilities for the creation of innovative and diverse glass objects.

- Advancements in Glass Machine Technology

The Evolution of Glass Machine Technology: From Hand-blown to Automated Production - Advancements in Glass Machine Technology

Glass machine technology has undergone a remarkable evolution over the years, moving from the traditional art of hand-blown glass production to the highly efficient and precise processes of automated production. This evolution has been driven by advancements in technology, leading to improved quality, efficiency, and productivity in the glass manufacturing industry.

The history of glass machine technology can be traced back to ancient civilizations where glass was first crafted by hand. The process of hand-blown glass production was a labor-intensive and time-consuming task, requiring skilled artisans to meticulously shape and manipulate molten glass into various forms and designs. While this technique produced exquisite and unique glass products, it was limited by its slow production speed and the potential for human error.

The Industrial Revolution brought significant changes to the glass industry with the introduction of mechanized glass machine technology. This era saw the invention of the first glass blowing machine, which automated the process of shaping molten glass into uniform shapes. This technological innovation revolutionized the glass production process, increasing efficiency and output while reducing production costs. However, these early glass machines were still limited in their capabilities and required significant human intervention to operate.

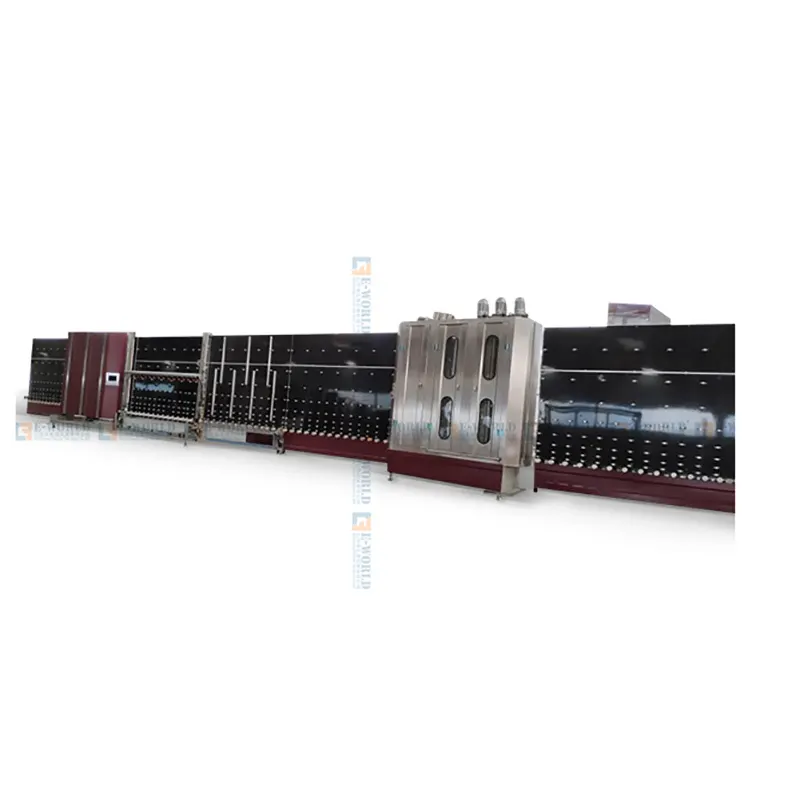

With the advent of modern technology, the glass manufacturing industry has witnessed a paradigm shift towards fully automated production processes. Advanced glass machine technology now encompasses a wide range of sophisticated equipment and machinery, including glass blowing machines, glass cutting machines, glass tempering furnaces, and glass processing systems. These state-of-the-art machines are equipped with precision controls, robotics, and advanced sensing technology, enabling them to produce high-quality glass products with unparalleled accuracy and consistency.

One of the most significant advancements in glass machine technology is the development of computer numerical control (CNC) systems for glass processing. These automated systems utilize computer programming and digital controls to precisely cut, shape, and polish glass with minimal human intervention. CNC glass cutting machines, for example, have revolutionized the glass fabrication process by reducing waste, improving accuracy, and increasing productivity. Additionally, the integration of robotics and automation has further streamlined glass production, allowing for seamless material handling, assembly, and quality control.

Furthermore, the integration of advanced sensing technology has greatly enhanced the efficiency and reliability of glass machine operations. Sensor-based systems are used to monitor and regulate various aspects of the glass manufacturing process, such as temperature, pressure, and thickness control. This level of automation and control ensures that glass products meet strict quality standards and specifications while minimizing the occurrence of defects and rejects.

In addition to technological advancements, the evolution of glass machine technology has also led to significant improvements in energy efficiency and environmental sustainability. Modern glass machines are designed to optimize energy consumption, reduce waste, and minimize environmental impact. Advanced heating and cooling systems, as well as recycling and reclamation technologies, have made glass production more eco-friendly and cost-effective.

In conclusion, the evolution of glass machine technology has transformed the glass manufacturing industry, paving the way for greater precision, efficiency, and innovation. The integration of advanced automation, robotics, CNC systems, and sensing technology has revolutionized the way glass products are produced, leading to higher quality, increased productivity, and reduced environmental impact. As technology continues to advance, the future of glass machine technology holds promise for further advancements and breakthroughs in the industry.

- Transition to Automated Glass Production

The glass industry has undergone a remarkable transformation over the years, with advancements in technology leading to a shift from traditional hand-blown techniques to the automated production of glass. This transition to automated glass production has revolutionized the way glass products are manufactured, improving efficiency, quality, and reducing costs. In this article, we will explore the evolution of glass machine technology and its impact on the industry.

The invention of the glass machine has significantly changed the way glass is produced. Hand-blown glass, which was once the standard method of production, required skilled artisans to meticulously shape and manipulate molten glass to create various products such as bottles, jars, and decorative items. However, this process was labor-intensive and time-consuming, limiting production capacity and driving up costs.

The introduction of automated glass machine technology has revolutionized the industry by streamlining the production process and increasing efficiency. These machines are equipped with advanced robotics, precision engineering, and computerized systems that can handle every stage of the production process with minimal human intervention. This has resulted in higher throughput, consistent quality, and reduced reliance on skilled labor.

One of the key advancements in glass machine technology is the development of glass forming machines, which can produce a wide range of glass products at a much faster rate than traditional methods. These machines use molds and automated processes to shape the molten glass into the desired product, significantly increasing production capacity and reducing lead times. This has allowed manufacturers to meet growing demand and compete in a global market.

Furthermore, the automation of glass cutting and processing has further improved the efficiency and precision of glass production. Automated cutting machines use advanced imaging and computer-controlled systems to measure, score, and break glass with remarkable accuracy, reducing waste and improving yield. This has resulted in cost savings and improved product quality, making automated glass cutting an essential component of modern glass production facilities.

The transition to automated glass production has also led to advancements in glass machine technology for surface treatment and decoration. Automated glass printing and coating machines can apply intricate designs, patterns, and coatings to glass products with precision and consistency, enhancing their aesthetic appeal and functionality. This has opened up new opportunities for innovative glass products in various industries, including architecture, automotive, and consumer goods.

In conclusion, the evolution of glass machine technology from hand-blown to automated production has revolutionized the glass industry. These advancements have improved efficiency, quality, and cost-effectiveness, making glass products more accessible and versatile than ever before. As technology continues to advance, we can expect further innovations in glass machine technology that will shape the future of the industry.

- Impact of Automated Production on the Glass Industry

Glass has been used by humans for thousands of years, and it has been a vital material in the construction, decoration, and packaging industries. Over time, the way glass has been manufactured has evolved significantly, and this evolution has been heavily influenced by the advancement of glass machine technology. In this article, we will explore the impact of automated production on the glass industry, and how it has revolutionized the way glass is produced.

The invention of the glass machine was a significant milestone in the history of glass production. Before the introduction of automated machines, glass was predominantly produced using the hand-blown technique. This method required skilled artisans to manipulate molten glass into the desired shape, a process that was labor-intensive and time-consuming. However, with the advent of glass machines, the production of glass became faster, more efficient, and less reliant on human labor.

One of the key impacts of automated production on the glass industry has been the increase in production capacity. Glass machines are capable of producing a larger volume of glass products in a shorter amount of time compared to traditional hand-blown methods. This has allowed manufacturers to meet the growing demand for glass products in various industries, from construction to consumer goods.

Moreover, the adoption of glass machines has significantly improved the quality and consistency of glass products. Automated production ensures that each glass object produced is uniform in size, shape, and thickness, thereby reducing the likelihood of defects and imperfections. This has not only increased the reliability of glass products but has also enhanced their overall aesthetic appeal.

Furthermore, the introduction of automated production has led to improvements in workplace safety and labor conditions. The manual process of hand-blown glass production was hazardous and physically demanding for workers. The use of glass machines has reduced the need for extensive physical labor, minimizing the risk of workplace injuries and improving the overall well-being of workers.

In addition to these benefits, the integration of automation in glass production has also led to advancements in the overall efficiency of manufacturing processes. Glass machines are equipped with advanced technology that allows for precise control over the production process, from shaping the glass to cooling and packaging the final product. This level of control has minimized wastage and optimized energy usage, making glass production more sustainable and environmentally friendly.

The evolution of glass machine technology has undoubtedly transformed the glass industry, offering numerous benefits to manufacturers, workers, and consumers alike. From increasing production capacity and improving product quality to enhancing workplace safety and efficiency, the impact of automated production on the glass industry has been profound. As technology continues to advance, it is likely that further innovations in glass machine technology will continue to shape the future of glass production, further revolutionizing the industry.

- Future Developments in Glass Machine Technology

Glass has been an essential material in human civilization for thousands of years, serving various purposes from basic containers to intricate works of art. Over the course of history, the production of glass has evolved from being labor-intensive and time-consuming to highly automated and efficient, thanks to the advancements in glass machine technology.

One of the most significant developments in glass machine technology is the transition from hand-blown glass production to automated production. Hand-blown glass, which has been around since ancient times, involves skilled artisans shaping molten glass into various forms using traditional tools such as blowpipes and molds. While this method is revered for its craftsmanship and artistic value, it is limited in terms of production capacity and consistency.

In contrast, automated production processes have revolutionized the glass industry by significantly increasing efficiency, quality, and output. Modern glass machines, equipped with advanced technology and robotics, can produce a wide range of glass products at a much faster rate and with superior precision. This shift towards automation has not only boosted productivity but also expanded the possibilities for glass applications in architecture, automotive, and electronics.

Looking ahead, the future developments in glass machine technology are poised to further elevate the capabilities of glass production. One of the key areas of advancement is in the integration of smart technology and artificial intelligence into glass machines. This includes the use of sensors and data analytics to optimize production processes, minimize waste, and improve overall product quality. Additionally, the implementation of AI-driven automation is expected to enhance the adaptability and flexibility of glass machines, allowing for swift adjustments in production to meet evolving market demands.

Furthermore, another exciting prospect in the future of glass machine technology is the development of sustainable and eco-friendly production solutions. As environmental awareness becomes increasingly important, the glass industry is under pressure to reduce its carbon footprint and embrace environmentally responsible practices. Innovations in glass machine technology are addressing this challenge by introducing energy-efficient equipment, recyclable materials, and clean production techniques. In doing so, the industry is not only meeting sustainability goals but also creating a new market for environmentally conscious consumers.

Moreover, the future of glass machine technology also holds promise in the realm of customization and personalization. With the advancement of digital design and 3D printing capabilities, glass machines are increasingly capable of producing highly customized and intricate glass products to meet specific customer requirements. This trend is particularly relevant in the architecture and interior design sectors where demand for unique and personalized glass solutions is on the rise.

In conclusion, the evolution of glass machine technology from hand-blown to automated production has paved the way for a new era of innovation and possibilities in the glass industry. The future developments in glass machine technology are positioned to further enhance efficiency, sustainability, and customization, shaping the industry to meet the demands of the 21st century and beyond. As we continue to witness the convergence of technology and tradition, the potential for glass machines to drive creativity, efficiency, and sustainability is indeed an exciting prospect for the future.

Conclusion

In conclusion, the evolution of glass machine technology from hand-blown to automated production has revolutionized the glass manufacturing industry. The advancements in technology have allowed companies, like ours with 10 years of experience in the industry, to improve efficiency, quality, and output. As we continue to witness the evolution of glass machine technology, we can expect further innovation and advancements that will shape the future of glass manufacturing. It is an exciting time for the industry, and we are proud to be a part of it.