The Ultimate Guide To Glass Machine Technology: How It Works And How It Can Benefit Your Business

Welcome to the ultimate guide to glass machine technology! If you're looking to understand how this innovative technology works and how it can elevate your business, you've come to the right place. In this comprehensive article, we'll dive into the inner workings of glass machine technology and explore the numerous ways it can benefit your business. Whether you're considering investing in this technology or simply want to stay informed about the latest advancements in the industry, this guide has everything you need to know. So, sit back, relax, and let us take you on a journey through the fascinating world of glass machine technology.

- Understanding the Basics of Glass Machine Technology

Understanding the Basics of Glass Machine Technology

Glass machine technology has revolutionized the way glass products are manufactured and processed. This has led to increased efficiency, improved quality, and decreased production costs. In this article, we will provide a detailed guide to understanding the basics of glass machine technology and how it can benefit your business.

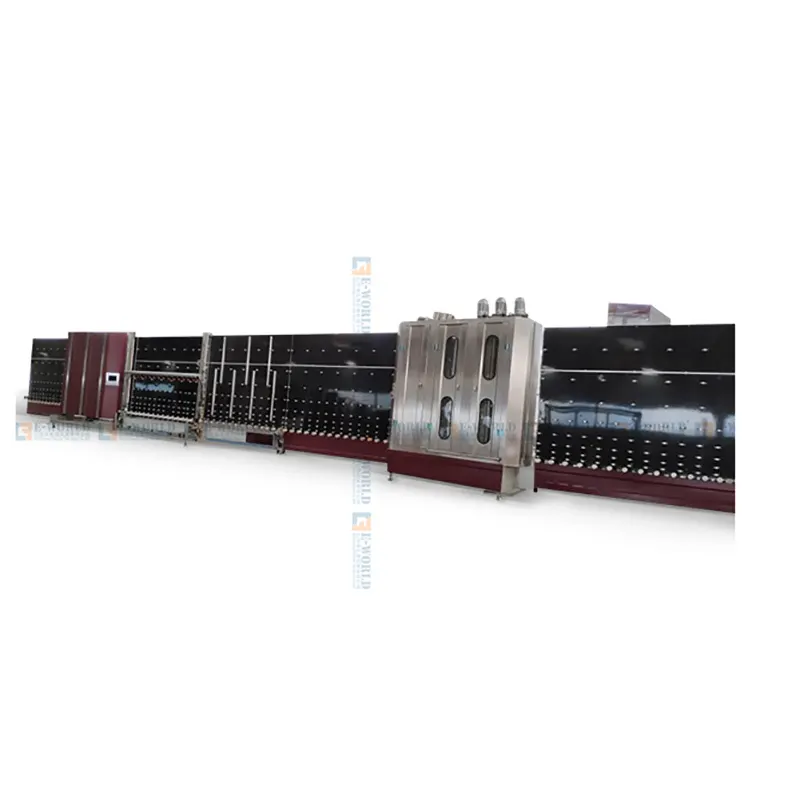

Glass machine technology encompasses a wide range of equipment and machinery used in the production, processing, and finishing of glass products. These machines are designed to perform various tasks such as cutting, shaping, drilling, grinding, polishing, and tempering glass. They are essential in the manufacture of a wide range of glass products including windows, doors, mirrors, tabletops, and decorative glass items.

One of the key components of glass machine technology is the glass cutting machine. This equipment is used to precisely cut large sheets of glass into smaller sizes according to specific dimensions. Modern glass cutting machines are equipped with computerized controls that ensure accurate and efficient cutting without creating any wastage. This technology has significantly reduced the time and effort required for glass cutting, resulting in increased production capacity and cost savings.

Glass shape edging and polishing machines are another essential aspect of glass machine technology. These machines are used to shape the edges of glass panels and polish them to a smooth finish. They are critical in enhancing the aesthetic appeal and safety of glass products. With advanced capabilities such as multi-axis CNC controls and automatic tool changers, these machines can produce complex shapes and achieve high-quality surface finishes.

In addition to cutting and shaping, glass drilling and milling machines are used to create holes and cutouts in glass panels. This is essential for the installation of hardware components such as hinges, handles, and locks in glass doors and windows. Glass drilling and milling machines are designed to maintain the structural integrity of the glass while achieving precise hole placement and size.

Tempering is an important process in the production of tempered glass, which is widely used in architectural and automotive applications. Tempering glass machine technology involves heating glass panels to a high temperature and then rapidly cooling them to induce surface compression and edge tension. This results in increased strength and safety properties compared to standard annealed glass. Glass tempering machines are equipped with advanced heating and quenching systems to achieve uniform and controlled tempering of glass panels.

Understanding the basics of glass machine technology can provide significant benefits to your business. By investing in modern glass machine technology, you can increase production efficiency, improve product quality, and reduce production costs. With the ability to perform complex operations with high precision and speed, glass machine technology opens up new opportunities for innovation and customization in glass product manufacturing.

In conclusion, glass machine technology has revolutionized the glass industry by providing advanced equipment and machinery for the production, processing, and finishing of glass products. By understanding the basics of glass machine technology and its various components, businesses can leverage these capabilities to enhance their manufacturing processes and meet the growing demands for high-quality glass products in the market.

- The Inner Workings of Glass Machine Technology

Glass machine technology is a crucial aspect of the glass industry that plays a significant role in shaping glass materials for various applications. This article aims to provide a comprehensive understanding of the inner workings of glass machine technology and how it can benefit businesses in the industry.

Glass machine technology involves a range of sophisticated machinery that is used in the production and processing of glass materials. From cutting and shaping to polishing and tempering, these machines are designed to streamline the manufacturing process and ensure the highest quality output.

One of the key components of glass machine technology is the glass cutting machine, which is used to cut large sheets of glass into smaller, more manageable sizes. This machine utilizes precision cutting tools and advanced software to accurately cut glass according to specific dimensions. This not only improves efficiency in the production process but also reduces material wastage, resulting in cost savings for businesses.

Another vital aspect of glass machine technology is the glass shaping and edging machine, which is used to shape and refine the edges of glass materials. This machine employs grinding and polishing tools to smoothen the edges of glass, creating a sleek and professional finish. This is essential for ensuring the safety and aesthetic appeal of glass products, particularly in applications such as windows, doors, and furniture.

Furthermore, glass tempering machines are a crucial component of glass machine technology, as they are responsible for enhancing the strength and durability of glass materials. Through a process of heating and rapid cooling, these machines create tempered glass, which is significantly stronger and more resistant to impact and thermal stress than standard glass. This makes it ideal for use in architectural and automotive applications, where safety and durability are paramount.

The benefits of investing in glass machine technology are numerous for businesses in the glass industry. Firstly, these machines enable greater precision and consistency in the manufacturing process, resulting in high-quality products that meet or exceed industry standards. This, in turn, enhances the reputation of a business and increases customer satisfaction, leading to potential growth and success.

Additionally, the efficiency and automation provided by glass machine technology can lead to significant cost savings for businesses. By minimizing manual labor and material wastage, these machines can improve productivity and reduce operational expenses, ultimately contributing to a more profitable bottom line.

Moreover, the use of advanced glass machine technology can also open up new opportunities for businesses to diversify their product offerings and cater to a wider range of customer needs. Whether it's custom-cut glass panels or tempered glass components, these machines empower businesses to expand their capabilities and explore new avenues for growth and innovation.

In conclusion, glass machine technology is an essential aspect of the glass industry that offers a range of benefits for businesses. From precision cutting and shaping to the production of tempered glass, these machines enable efficiency, quality, and innovation in the manufacturing process. By investing in glass machine technology, businesses can position themselves for success and leadership in the competitive glass market.

- The Advantages of Implementing Glass Machine Technology in Your Business

Glass machine technology has revolutionized the way businesses in the glass industry operate. From cutting and shaping to finishing and polishing, these advanced machines have proven to be incredibly beneficial in enhancing productivity and efficiency. In this ultimate guide to glass machine technology, we will explore how it works and the myriad of advantages it can bring to your business.

One of the key advantages of implementing glass machine technology in your business is the significant improvement in accuracy and precision. These machines are equipped with sophisticated computerized systems that can execute intricate and precise measurements, ensuring that the glass pieces are cut and shaped with utmost accuracy. This level of precision not only enhances the overall quality of the glass products but also minimizes the margin of error, thus reducing wastage and rework.

Furthermore, glass machine technology also offers a substantial increase in production efficiency. With automated processes and advanced robotics, these machines can perform tasks at a much faster pace compared to traditional manual methods. This acceleration in production not only allows businesses to meet tight deadlines and fulfill large orders but also enables them to handle a higher volume of work without compromising on quality.

In addition to accuracy and efficiency, glass machine technology also contributes to a safer working environment. The automated nature of these machines reduces the physical demands on workers and minimizes the risk of accidents and injuries associated with manual handling of glass materials. This not only ensures the well-being of employees but also mitigates potential liabilities for the business.

Moreover, the implementation of glass machine technology can lead to cost savings in the long run. While the initial investment in these machines may seem substantial, the improved efficiency and reduced wastage ultimately translate to lower production costs. Additionally, the enhanced quality of the glass products can command higher prices in the market, thus driving greater profitability for the business.

Another advantage of implementing glass machine technology is the versatility it offers in terms of customization and design. These machines are capable of executing complex and intricate designs with ease, allowing businesses to cater to a diverse range of customer requirements. Whether it's custom-sized glass panels or intricate patterns, these machines can fulfill even the most unique and demanding design specifications, thereby expanding the business's market reach and appeal.

Furthermore, glass machine technology also contributes to sustainability and environmental consciousness. By optimizing the use of raw materials and minimizing wastage, these machines promote responsible and efficient utilization of resources. Additionally, the reduction in energy consumption and carbon emissions further reinforces the eco-friendly benefits of implementing advanced glass machine technology in a business.

In conclusion, the advantages of implementing glass machine technology in your business are undeniable. The enhanced accuracy, efficiency, safety, cost savings, versatility, and sustainability that these machines offer make them indispensable assets in the glass industry. By embracing and integrating this advanced technology, businesses can elevate their operations to new heights and achieve greater success in a competitive market.

- How Glass Machine Technology Can Improve Efficiency and Quality

Glass machine technology has significantly transformed the glass manufacturing industry, revolutionizing the way glass products are produced. With advancements in automation, precision, and efficiency, glass machine technology has become an indispensable asset for businesses seeking to improve their production processes and deliver high-quality glass products to their customers.

One of the key benefits of glass machine technology is its ability to enhance efficiency in the glass manufacturing process. Traditional methods of glass production often relied on manual labor and were subject to human error, leading to inconsistent product quality and longer production times. However, with the introduction of advanced glass machine technology, manufacturers can now streamline their production processes, reduce human intervention, and increase the speed and accuracy of glass manufacturing.

Glass cutting, shaping, and finishing are some of the critical processes in glass manufacturing, and these tasks have been significantly optimized through the use of glass machine technology. Automated glass cutting machines, for example, can precisely cut glass sheets to the desired dimensions with minimal errors, eliminating the need for manual measurements and cutting. This not only reduces production time but also minimizes wastage, resulting in cost savings for manufacturers. Similarly, glass shaping and finishing processes, such as grinding and polishing, have also been automated with the use of advanced machinery, ensuring consistent and high-quality glass products.

Quality is another vital aspect of glass manufacturing, and glass machine technology plays a pivotal role in ensuring the production of superior quality glass products. By utilizing advanced sensors, computerized systems, and precise control mechanisms, glass machine technology can monitor and maintain the highest standards of quality during the manufacturing process. This results in glass products that are more uniform, free from defects, and meet the strictest industry standards and customer expectations. Additionally, the use of automated inspection systems further enhances the quality control process, enabling manufacturers to identify and address any potential defects or irregularities in the glass products before they reach the market.

Aside from improving efficiency and quality, glass machine technology also offers several other benefits to businesses in the glass industry. For instance, automated glass machines require less human labor, reducing the dependency on manual workers and minimizing the risk of workplace accidents. This not only enhances the safety of the production environment but also allows manufacturers to reallocate resources to more value-added tasks, such as product design and innovation. Furthermore, the increased precision and consistency achieved through glass machine technology can also lead to higher customer satisfaction and loyalty, as well as a stronger competitive advantage in the market.

In conclusion, the advancements in glass machine technology have brought about significant improvements in the efficiency and quality of glass manufacturing. By leveraging automated processes, precise control mechanisms, and advanced inspection systems, businesses can enhance their production processes, minimize wastage, and deliver high-quality glass products to their customers. As the glass industry continues to evolve, it is clear that glass machine technology will play an increasingly important role in shaping the future of glass manufacturing.

- Implementing Glass Machine Technology: A Step-By-Step Guide

Glass machine technology is rapidly changing the game for businesses in the glass industry. With the implementation of advanced machinery, companies are able to streamline their production processes, improve product quality, and ultimately increase their bottom line. In this comprehensive guide, we will walk you through the ins and outs of glass machine technology, how it works, and the benefits it can bring to your business. We will also provide you with a step-by-step guide on how to implement this technology into your operations.

Understanding Glass Machine Technology

Glass machine technology refers to the use of specialized machinery in the production and processing of glass products. This can include cutting, grinding, polishing, and shaping machines, as well as more advanced automated systems for glass handling and fabrication. These machines are designed to maximize efficiency, precision, and consistency, ultimately leading to higher quality products and lower production costs.

How Glass Machine Technology Works

Glass machine technology works by automating and streamlining the various processes involved in glass production. This includes cutting glass to precise measurements, shaping it into specific forms, and polishing the finished products. Advanced machinery can also handle more complex tasks such as creating custom designs and patterns on glass surfaces.

One of the key components of glass machine technology is computer numerical control (CNC) systems, which allow for the precise control and automation of various manufacturing processes. These systems use computer-aided design (CAD) software to create detailed 3D models of the desired glass products, which are then translated into machine code to direct the production machinery.

Benefits for Your Business

Implementing glass machine technology into your business operations can have numerous benefits. First and foremost, it can significantly improve the quality of your glass products. By automating various processes, you can ensure greater precision and consistency in your production, leading to fewer defects and higher customer satisfaction.

Additionally, glass machine technology can also have a positive impact on your bottom line. By increasing efficiency and reducing the need for manual labor, you can lower your production costs and improve your overall profitability. Furthermore, automation can also lead to faster production times, allowing you to fulfill orders more quickly and potentially take on more business.

Implementing Glass Machine Technology: A Step-By-Step Guide

Now that you understand the benefits of glass machine technology, you may be wondering how to incorporate it into your own operations. Here is a step-by-step guide to help you get started:

1. Assess Your Needs: The first step is to evaluate your current production processes and identify areas where glass machine technology could be beneficial. This could include analyzing your current production volumes, product quality, and operational inefficiencies.

2. Research Machinery Options: Once you have identified areas for improvement, it's time to research the various glass machine technology options available to you. This may include CNC cutting machines, polishing systems, or fully automated glass fabrication lines.

3. Determine Costs and ROI: Before making any purchases, it's important to carefully consider the costs and potential return on investment for implementing glass machine technology. This may involve obtaining quotes from machinery suppliers and calculating the potential savings and increased revenue from the technology.

4. Plan for Implementation: Once you have chosen the right machinery for your needs, it's time to plan for its implementation. This may involve redesigning your production layout, training staff on the new technology, and potentially making adjustments to your product designs.

5. Monitor and Optimize: After implementing glass machine technology, it's important to monitor its performance and continue to optimize your production processes. This may involve making further adjustments to your machinery settings, refining your production workflows, and ensuring that your staff are fully trained and proficient in using the new technology.

In conclusion, glass machine technology is a game-changer for businesses in the glass industry. By implementing advanced machinery and automation systems, companies can significantly improve their production processes, product quality, and overall profitability. By following the step-by-step guide outlined in this article, you can take the necessary steps to incorporate this technology into your own operations and reap its many benefits.

Conclusion

In conclusion, the glass machine technology has the potential to revolutionize the way your business operates. With our 10 years of experience in the industry, we have seen firsthand the incredible benefits that this technology can bring to companies. From increased efficiency and productivity to higher quality products, the advantages are clear. By understanding how glass machine technology works and how it can benefit your business, you can take the necessary steps to incorporate this innovative technology into your operations. Embracing this cutting-edge technology is a surefire way to stay ahead of the competition and take your business to new heights.