Perfecting The Finish: The Ultimate Guide To Glass Edge Beveling Machines

Are you tired of rough, uneven edges on your glass projects? Look no further! In this comprehensive guide, we will take you through the ins and outs of glass edge beveling machines – the perfect solution for achieving sleek, polished finishes on your glasswork. Whether you're a hobbyist or a professional, this ultimate guide will provide you with all the information you need to perfect the finish on your glass projects. From understanding the different types of machines to tips for selecting the right one for your needs, this guide has it all. So, if you're ready to take your glasswork to the next level, dive into our guide and discover the magic of glass edge beveling machines.

- Introduction to Glass Edge Beveling Machines

If you’re in the business of working with glass, then you know how important it is to have a perfect finish on your edges. Glass edge beveling machines are an essential tool for achieving this, and in this ultimate guide, we’ll take you through everything you need to know to perfect the finish on your glass edges.

Glass edge beveling machines are designed to create a clean and polished finish on the edges of glass panels. These machines are essential for any glass processing facility, as they help to eliminate the sharp edges that are often left behind after cutting or shaping glass. Not only do beveled edges look cleaner and more professional, but they also reduce the risk of injury from handling sharp edges.

There are several different types of glass edge beveling machines available, each designed for specific applications and levels of production. Some machines are small and portable, designed for use in smaller workshops or for on-site jobs, while others are large, industrial machines capable of processing large volumes of glass.

When choosing a glass edge beveling machine, it’s important to consider the size and type of glass panels you’ll be working with, as well as the level of production you require. Some machines are capable of processing curved or irregular shapes, while others are designed specifically for straight edges. Additionally, some machines offer automated features, such as adjustable speed and thickness settings, which can save time and improve efficiency.

The process of beveling glass edges involves several steps, including rough grinding, fine grinding, polishing, and finally, washing and drying the glass. Each step is crucial for achieving a perfect finish, and the right machine will be capable of performing each step with precision and accuracy.

In addition to the type and size of the machine, it’s important to consider the quality and durability of the machine. Look for machines that are constructed from high-quality materials and designed for heavy-duty use, as this will ensure that your machine lasts for years to come.

In conclusion, glass edge beveling machines are an essential tool for achieving a perfect finish on glass edges. When choosing a machine, consider the size and type of glass panels you’ll be working with, as well as the level of production you require. Look for a machine that is capable of performing each step of the beveling process with precision and accuracy, and ensure that it is constructed from high-quality materials designed for heavy-duty use. With the right machine, you can perfect the finish on your glass edges and ensure that your finished products are clean, professional, and safe to handle.

- Understanding the Importance of Perfect Finishing in Glass Edge Beveling

Understanding the Importance of Perfect Finishing in Glass Edge Beveling

Glass edge beveling machines are essential tools in the glass manufacturing industry, as they allow for the precise shaping and finishing of glass edges. The finishing process is particularly crucial in achieving the perfect beveled edge, as it not only enhances the aesthetic appeal of the glass but also ensures its durability and safety. In this article, we will delve into the importance of perfect finishing in glass edge beveling and how it contributes to the overall quality of the final product.

One of the key aspects of glass edge beveling is achieving a smooth and polished finish. This is vital for both decorative and practical reasons. A smooth finish not only enhances the appearance of the glass but also prevents potential injury from sharp edges. A glass edge beveling machine plays a critical role in achieving this perfect finish by precisely grinding and polishing the edges of the glass to create a uniform and flawless beveled edge. With the use of advanced technology and precision engineering, these machines can produce consistent results, ensuring that every piece of glass meets the highest standards of quality and safety.

Furthermore, the perfect finishing of glass edges is essential for ensuring the longevity and durability of the glass. A well-finished beveled edge is less prone to chipping, cracking, or other forms of damage, which can compromise the structural integrity of the glass. By investing in a high-quality glass edge beveling machine, manufacturers can produce glass products that are not only visually appealing but also highly resilient and long-lasting. This is particularly important in applications where the glass is exposed to external elements or heavy usage, such as in architectural structures, furniture, or automotive components.

Another crucial aspect of perfect finishing in glass edge beveling is the precision and accuracy of the beveled edges. The beveling process involves grinding and shaping the edges of the glass at specific angles, which requires a high degree of accuracy to achieve the desired results. A well-calibrated glass edge beveling machine is capable of achieving the precise angles and dimensions required for each individual project, allowing for a customized and tailored approach to glass edge beveling. This precision in finishing not only enhances the aesthetic appeal of the glass but also ensures that it fits seamlessly into its intended application, whether it be a window, mirror, or decorative glass panel.

In conclusion, the importance of perfect finishing in glass edge beveling cannot be overstated. From enhancing the aesthetic appeal to ensuring the durability and safety of the glass, the finishing process is a critical aspect of the overall quality of the final product. By using high-quality glass edge beveling machines, manufacturers can achieve the perfect finish that meets the highest standards of craftsmanship and precision, ultimately delivering superior glass products to their customers.

- Choosing the Right Glass Edge Beveling Machine for Your Needs

When it comes to perfecting the finish on glass edges, choosing the right glass edge beveling machine for your needs is crucial. With so many options available on the market, it can be overwhelming to find the perfect machine for your specific requirements. In this ultimate guide to glass edge beveling machines, we will explore the different types of machines available, the key features to look for, and how to choose the right machine for your needs.

Types of Glass Edge Beveling Machines

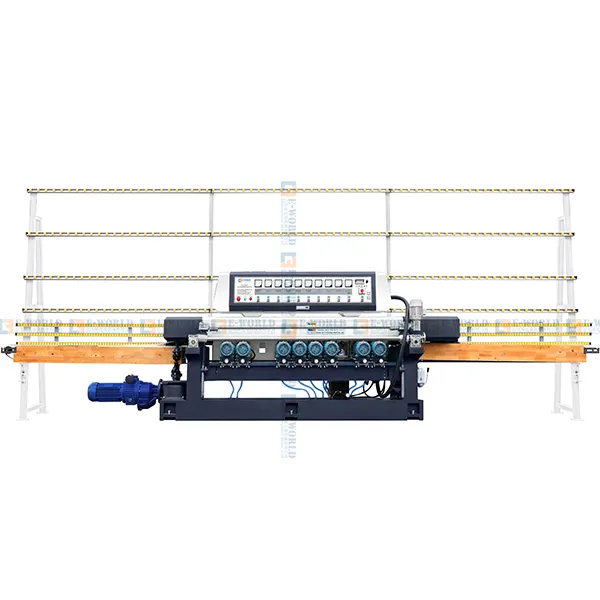

There are several different types of glass edge beveling machines available, each with its own unique features and capabilities. The most common types of machines include straight line edging machines, double-edging machines, and shape beveling machines. Straight line edging machines are ideal for straight edges and are often used in the production of standard glass panels. Double-edging machines are able to process two edges at the same time, increasing efficiency and reducing production time. Shape beveling machines are designed for more complex bevel shapes and angles, making them suitable for custom glass products.

Key Features to Look For

When choosing a glass edge beveling machine, there are several key features to consider. The size and capacity of the machine will determine the maximum size and thickness of glass that can be processed. The quality and precision of the beveling process is also important, so look for machines with high-quality diamond grinding wheels and advanced control systems. Additionally, consider the speed and efficiency of the machine, as well as any additional features such as automatic tool changers and integrated cooling systems.

Choosing the Right Machine for Your Needs

When choosing a glass edge beveling machine, it's important to consider your specific production requirements and budget. If you primarily work with standard glass panels and straight edges, a straight line edging machine may be sufficient for your needs. However, if you require more complex shapes and angles, a shape beveling machine may be a better fit. Consider the volume of glass you need to process, as well as any future growth or expansion plans. It's also important to factor in the level of expertise and support available for the machine, as well as any maintenance and training requirements.

In conclusion, choosing the right glass edge beveling machine for your needs is essential for perfecting the finish on glass edges. By considering the different types of machines available, key features to look for, and your specific production requirements, you can make an informed decision and invest in a machine that will meet your needs for years to come. With the right machine in your workshop, you can ensure a high-quality finish on all your glass products.

- Tips and Techniques for Achieving the Perfect Finish with Glass Edge Beveling Machines

Glass edge beveling machines are an essential tool for achieving the perfect finish on glass edges. Whether you are a professional glassworker or a DIY enthusiast, knowing how to use a glass edge beveling machine effectively can make all the difference in the quality of your finished piece. In this ultimate guide, we will provide you with tips and techniques for using glass edge beveling machines to achieve a flawless finish.

One of the most important aspects of using a glass edge beveling machine is understanding the different types of bevels that can be achieved. Beveling machines are capable of creating a variety of bevel profiles, including straight, pencil, and OG (old German) bevels. Each type of bevel requires different techniques and settings on the machine, so it is essential to familiarize yourself with the capabilities of your specific machine.

When using a glass edge beveling machine, it is crucial to start with the right glass thickness and type. Thicker glass will require a more robust beveling machine, while thinner glass can be handled with a lighter-duty machine. Additionally, different types of glass, such as tempered or annealed, may require adjustments to the machine settings to achieve the perfect finish.

In order to achieve a flawless finish with a glass edge beveling machine, it is important to pay attention to the speed and pressure at which the glass is fed through the machine. Too much speed or pressure can result in chipping or breakage, while too little can result in an uneven or incomplete bevel. Finding the right balance of speed and pressure requires practice and patience, but it is essential for achieving the perfect finish.

Furthermore, maintaining the proper alignment of the glass as it passes through the machine is crucial for achieving a consistent and symmetrical bevel. A misaligned piece of glass can result in an uneven or crooked bevel, so it is important to take the time to ensure that the glass is properly positioned before starting the beveling process.

In addition to technique, proper maintenance of the glass edge beveling machine is essential for achieving the perfect finish. Regular cleaning and lubrication of the machine's moving parts will ensure smooth and precise operation, while periodic adjustment and calibration of the machine's settings will help maintain the quality of the finished bevels.

In conclusion, mastering the art of using a glass edge beveling machine requires a combination of skill, knowledge, and attention to detail. By understanding the capabilities of your machine, paying attention to technique, and maintaining the machine properly, you can achieve the perfect finish on your glass edges. So, whether you are a professional glassworker or a DIY enthusiast, the tips and techniques provided in this guide will help you achieve flawless bevels with your glass edge beveling machine.

- Maintaining and Troubleshooting Glass Edge Beveling Machines

Glass edge beveling machines are essential tools in the glass manufacturing industry, helping to achieve the perfect finish on glass edges. However, like any other machinery, these machines require regular maintenance and troubleshooting to ensure they continue to operate at peak performance. In this comprehensive guide, we will delve into the various aspects of maintaining and troubleshooting glass edge beveling machines, providing valuable insights for glass manufacturers and technicians.

Routine maintenance is crucial for ensuring the longevity and efficiency of glass edge beveling machines. One of the most important maintenance tasks is keeping the machine clean and free of debris. Dust, glass particles, and other contaminants can accumulate in the machine's components, leading to inefficiencies and potential damage. Regular cleaning with appropriate tools and cleaning agents is necessary to prevent such issues.

In addition to cleaning, the machine's moving parts, such as the beveling wheels and conveyors, should be lubricated regularly to reduce friction and wear. Proper lubrication not only extends the lifespan of the machine but also ensures that the glass edges are beveled smoothly and accurately. It is important to use lubricants recommended by the machine's manufacturer to prevent any adverse effects on the machine's components.

Furthermore, inspecting and replacing worn or damaged parts is essential for the proper functioning of the glass edge beveling machine. Over time, components such as belts, bearings, and cutting tools may wear out and require replacement. Regular inspections can help identify these issues early on, preventing costly repairs and minimizing downtime.

Troubleshooting is an inevitable part of maintaining glass edge beveling machines. When the machine's performance is compromised, troubleshooting allows technicians to identify and rectify the issue promptly. One common issue is misalignment, which can result in uneven beveling and lower-quality finishes. This can often be resolved by adjusting and aligning the machine's components according to the manufacturer's specifications.

Another common problem is vibration, which can lead to poor-quality beveling and potential damage to the glass. Vibration can be caused by various factors, such as misalignment, worn components, or imbalance. Identifying the root cause of the vibration is crucial for addressing the issue effectively.

Electrical and electronic issues, such as malfunctioning sensors or control units, can also hamper the machine's performance. Troubleshooting these issues may require the expertise of a qualified technician, as working with electrical components requires specific knowledge and skills to ensure safety and proper resolution.

In conclusion, maintaining and troubleshooting glass edge beveling machines is vital for ensuring optimal performance and high-quality finishes. By following a comprehensive maintenance regimen and promptly addressing any issues that arise, glass manufacturers can maximize the efficiency and longevity of their beveling machines, ultimately enhancing their production capabilities and product quality.

Conclusion

In conclusion, after 10 years of experience in the industry, we can confidently say that glass edge beveling machines are essential for perfecting the finish of glass products. They offer precision, efficiency, and consistency in creating beveled edges, making them an invaluable tool for any glass manufacturing business. Investing in a high-quality glass edge beveling machine is a wise decision that can greatly improve the overall quality and aesthetics of your glass products. With the ultimate guide to glass edge beveling machines, we hope that you have gained a comprehensive understanding of their importance and how to choose the right machine for your specific needs. Here’s to perfecting the finish and taking your glass products to the next level!