Mastering The Art Of Glass Edge Beveling With The Latest Machine Technology

Are you looking to elevate your glass edge beveling skills to the next level? Look no further! In this article, we will explore the latest advancements in machine technology that are revolutionizing the art of glass edge beveling. Whether you are a seasoned professional or just starting out in the industry, this article will provide valuable insights and tips to help you master the craft. Read on to discover how you can take your glass edge beveling to new heights with the latest machine technology.

- Understanding the Importance of Glass Edge Beveling

Glass edge beveling is a crucial step in the process of creating high-quality glass products. Whether it be mirrors, windows, or glass furniture, the quality of the beveled edge plays a significant role in the overall aesthetic appeal and structural integrity of the glass. In recent years, advancements in machine technology have revolutionized the art of glass edge beveling, making it easier and more precise than ever before. This article aims to explore the importance of glass edge beveling and how the latest machine technology has elevated the craft to new heights.

Glass edge beveling is the process of shaping and polishing the edges of glass to create a decorative and functional finish. The beveled edge not only adds a touch of elegance to the glass but also serves a practical purpose by removing sharp edges that could be hazardous. Additionally, a well-executed beveled edge can enhance the overall strength and durability of the glass, making it less prone to chipping and cracking.

With the advancements in glass edge beveling machine technology, the process has become more efficient and precise. These machines are equipped with cutting-edge tools and features that allow for automated beveling with unparalleled accuracy. The use of CNC (Computer Numerical Control) technology enables the machines to execute complex bevel designs with exact measurements, ensuring consistency and uniformity across a large volume of glass panels. This level of precision is not achievable through traditional manual beveling methods, making machine technology a game-changer in the industry.

One of the key advantages of using glass edge beveling machines is the ability to achieve a variety of bevel profiles. Whether it be straight-line bevels, pencil polish, or custom-designed shapes, the flexibility of these machines allows for endless creative possibilities. This level of customization is invaluable for architects, interior designers, and manufacturers who seek to differentiate their glass products in a competitive market.

In addition to precision and flexibility, glass edge beveling machines also offer efficiency and cost-effectiveness. The automated process reduces the labor and time required for manual beveling, ultimately leading to higher productivity and reduced production costs. Furthermore, the consistency achieved through machine beveling minimizes material wastage, contributing to sustainability and environmental responsibility.

Another significant benefit of utilizing glass edge beveling machines is the improvement in safety and quality control. The automated process eliminates the risks associated with manual handling of glass, reducing the chances of accidents and injuries in the workplace. Moreover, the precision of machine beveling results in superior edge quality, free from imperfections and irregularities commonly found in hand-finished edges.

In conclusion, glass edge beveling is an integral part of the glass manufacturing process, and the latest machine technology has revolutionized the craft. The precision, flexibility, efficiency, and safety offered by glass edge beveling machines make them indispensable tools for achieving high-quality, aesthetically pleasing glass products. As technology continues to innovate, the art of glass edge beveling will undoubtedly evolve, shaping the future of the glass industry.

- Exploring the Latest Machine Technology for Glass Edge Beveling

Glass edge beveling is a crucial process in the glass manufacturing industry, as it enhances the aesthetic appeal and safety of the glass. With the rapid advancements in technology, the latest machine technology for glass edge beveling has revolutionized the way this process is carried out. In this article, we will explore the latest machine technology for glass edge beveling and its impact on mastering the art of this process.

One of the key advancements in glass edge beveling technology is the introduction of computerized numerical control (CNC) machines. These machines are equipped with advanced software that allows for precise control and customization of the beveling process. This level of control enables manufacturers to achieve a high level of precision and consistency in the beveling of glass edges, resulting in a superior finish.

Furthermore, the latest glass edge beveling machines are designed to be highly efficient, with the ability to process large volumes of glass in a short amount of time. This not only increases productivity but also allows manufacturers to meet tight production deadlines without compromising on the quality of the beveled edges.

In addition to efficiency, the latest machines for glass edge beveling also come with enhanced safety features. These machines are equipped with sensors and safety guards to prevent accidents and ensure the well-being of operators. This is particularly important in an industry where safety is paramount, and the latest technology has made significant strides in addressing this concern.

Another noteworthy aspect of the latest glass edge beveling machines is their versatility. These machines are capable of beveling glass of various shapes and sizes, making them suitable for a wide range of glass products. Whether it's large architectural panels or small decorative pieces, the latest machines can cater to diverse beveling requirements, making them an indispensable asset for glass manufacturers.

Moreover, the latest technology in glass edge beveling machines also offers compatibility with a range of glass types, including standard float glass, tempered glass, and even laminated glass. This flexibility allows manufacturers to explore new possibilities in design and functionality, leading to innovative applications of beveled glass in various industries.

It's also worth mentioning that the latest glass edge beveling machines are designed with sustainability in mind. With energy-efficient components and optimized processes, these machines contribute to reducing energy consumption and minimizing waste, aligning with the industry's drive towards eco-friendly practices.

In conclusion, the latest machine technology for glass edge beveling has brought significant advancements to the industry, enabling manufacturers to master the art of this process with unparalleled precision, efficiency, safety, versatility, and sustainability. As technology continues to evolve, we can expect further innovations that will continue to elevate the standards of glass edge beveling, shaping the future of the glass manufacturing industry.

- Mastering the Techniques for Glass Edge Beveling with Advanced Machinery

Glass edge beveling is a crucial technique in the glass manufacturing industry. It involves cutting and polishing the edge of a piece of glass to create a beveled or angled edge. This process not only enhances the aesthetics of the glass but also improves its durability and strength. With the advancement of technology, the use of glass edge beveling machines has become increasingly popular, allowing for precise and efficient results. In this article, we will delve into the techniques for glass edge beveling with advanced machinery and how it has revolutionized the industry.

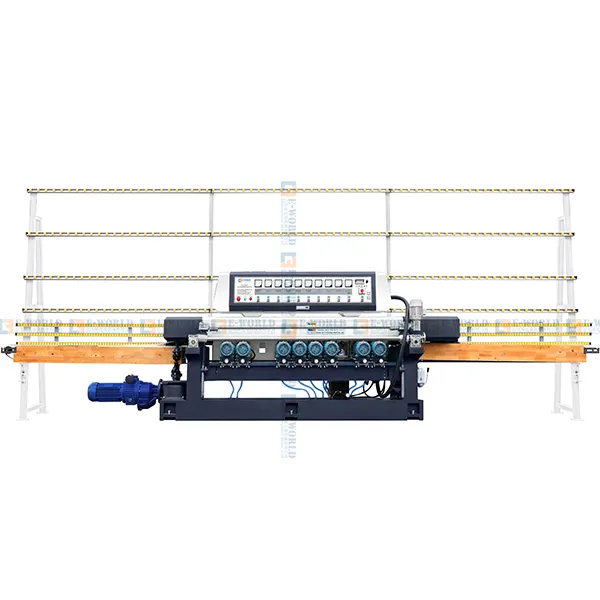

Advanced glass edge beveling machines are equipped with state-of-the-art technology that enables precise cutting and polishing of glass edges. These machines utilize diamond grinding wheels and advanced polishing techniques to achieve smooth, uniform beveled edges. The use of computerized controls also ensures accuracy and consistency in the beveling process, resulting in flawless glass edges.

One of the key techniques in glass edge beveling with advanced machinery is the use of computer-aided design (CAD) software. This software allows for precise designing of the beveled edge, including the angle and width of the bevel. The CAD software then communicates with the glass edge beveling machine, guiding it to cut and polish the glass according to the design specifications. This level of precision and control ensures that the desired beveled edge is achieved with minimal margin for error.

Another important technique in glass edge beveling with advanced machinery is the use of automatic edge detection and measurement systems. These systems utilize advanced sensors and cameras to accurately detect the edges of the glass and measure their dimensions. This information is then used to program the glass edge beveling machine to cut and polish the glass with the precise dimensions required for the beveled edge. This automated process not only saves time but also eliminates human error, resulting in consistently accurate beveled edges.

Furthermore, the use of advanced cooling and lubrication systems in glass edge beveling machines is another crucial technique that contributes to the efficiency and quality of the beveling process. These systems help to dissipate the heat generated during the grinding and polishing of the glass, preventing thermal damage and ensuring a high-quality finish. Additionally, the use of water-based coolant and lubricants reduces friction, resulting in smoother and more precise beveling.

In conclusion, mastering the techniques for glass edge beveling with advanced machinery has revolutionized the glass manufacturing industry. The use of computer-aided design software, automatic edge detection and measurement systems, and advanced cooling and lubrication systems has significantly improved the precision, efficiency, and quality of glass edge beveling. As technology continues to advance, the future of glass edge beveling machines looks promising, with further advancements expected to enhance the process even more.

- Achieving Precision and Quality in Glass Edge Beveling

Glass edge beveling is a delicate and crucial process in the manufacturing and finishing of glass products. Achieving precision and quality in glass edge beveling is essential for ensuring the durability, safety, and aesthetic appeal of the final glass product. With the latest machine technology, manufacturers and glass artisans can now master the art of glass edge beveling with unprecedented accuracy and efficiency.

The keyword of this article is "glass edge beveling machine," and we will delve into the importance of this technology in achieving precision and quality in glass edge beveling.

Glass edge beveling machines are designed to accurately and consistently create the angled edge on glass surfaces, providing a smooth and polished finish. These machines utilize advanced cutting and polishing techniques to achieve precise beveled edges, ensuring that the glass meets the required specifications for strength, safety, and visual appeal.

One of the primary advantages of using glass edge beveling machines is the ability to achieve consistent and uniform beveled edges across a wide range of glass thicknesses and shapes. This level of precision is crucial for ensuring the structural integrity and safety of the final glass product, especially in applications where the glass will be subject to heavy loads or impacts.

In addition to precision, glass edge beveling machines also play a crucial role in enhancing the visual appeal of glass products. The smooth and polished beveled edge adds a touch of elegance and sophistication to the glass, making it ideal for a wide range of applications, including architectural glass, furniture, mirrors, and decorative pieces.

Furthermore, the latest advancements in machine technology have led to the development of glass edge beveling machines that are not only precise but also highly efficient. These machines are capable of handling high volumes of glass processing with minimal downtime, making them an invaluable asset for manufacturers seeking to optimize their production processes and meet tight deadlines.

Another key feature of modern glass edge beveling machines is their ability to accommodate custom designs and intricate patterns on the beveled edge. This level of customization and flexibility allows artisans and designers to unleash their creativity and create unique glass products that stand out in the market.

Moreover, the integration of advanced automation and computerized controls in glass edge beveling machines has significantly reduced the margin of error and the need for manual intervention. This results in higher production yields, lower labor costs, and ultimately, a more competitive edge for glass manufacturers.

In conclusion, glass edge beveling machines have revolutionized the art of glass processing by enabling manufacturers and artisans to achieve unparalleled precision and quality in the creation of beveled glass edges. With the latest machine technology, the possibilities for creating stunning and durable glass products are endless, making this technology a must-have for any glass manufacturing facility or artisan workshop.

- Advantages of Utilizing the Latest Machine Technology for Glass Edge Beveling

The art of glass edge beveling has evolved significantly with the advancement of technology in recent years. The use of the latest machine technology has revolutionized the way glass edges are beveled, offering a range of advantages that were previously unimaginable. This article will delve into the various benefits of utilizing the latest machine technology for glass edge beveling, highlighting the ways in which it has transformed the industry.

First and foremost, the use of the latest machine technology for glass edge beveling has significantly improved efficiency and productivity. These machines are capable of handling large volumes of glass with precision and speed, reducing the time and labor required for beveling edges. This means that businesses can complete projects in a fraction of the time it would have taken with traditional methods, leading to increased productivity and ultimately higher profits.

In addition to improved efficiency, the latest machine technology also offers unmatched precision in glass edge beveling. These machines are equipped with advanced sensors and cutting-edge software that ensure the accuracy and consistency of each beveled edge. This level of precision is impossible to achieve with manual methods, and it results in a higher quality finished product that is free from imperfections.

Furthermore, the use of glass edge beveling machines has improved safety in the workplace. These machines are designed with a range of safety features that minimize the risk of accidents and injuries, protecting workers and preventing damage to the glass. This not only creates a safer environment for employees but also reduces the likelihood of costly mishaps that can occur during the beveling process.

Another advantage of utilizing the latest machine technology for glass edge beveling is the ability to achieve complex and intricate designs. These machines are capable of producing a wide range of bevel shapes and angles, allowing for greater creativity and customization in the finished product. This level of versatility opens up new possibilities for designers and architects, as they are no longer limited to simple, straight beveled edges.

In addition to these benefits, the latest machine technology for glass edge beveling also offers cost savings in the long run. While the upfront investment in these machines may be significant, the efficiency and precision they provide ultimately lead to reduced material wastage and rework. This translates to lower production costs and higher profitability over time, making it a worthwhile investment for businesses in the glass industry.

Overall, the advantages of utilizing the latest machine technology for glass edge beveling are clear. From improved efficiency and precision to enhanced safety and design capabilities, these machines have transformed the way glass edges are beveled. As technology continues to advance, it is likely that these benefits will only continue to grow, further solidifying the importance of embracing the latest machine technology in the art of glass edge beveling.

Conclusion

In conclusion, mastering the art of glass edge beveling with the latest machine technology is essential for staying competitive in the industry. With 10 years of experience, our company has honed our skills and expertise to provide top-notch glass edge beveling services that meet the highest standards of quality and precision. By investing in the latest machine technology, we are able to deliver superior results that exceed our customers' expectations. We are committed to staying at the forefront of innovation in the glass beveling sector, ensuring that our clients receive the best possible products and services. With our dedication to excellence, we are confident that we will continue to thrive in the industry for many years to come. Thank you for reading and for your continued support!