Revolutionizing Windows: The Vertical Glass Washing Machine

Are you tired of spending hours cleaning your windows and struggling to reach every corner? Say goodbye to traditional window cleaning methods and revolutionize your window cleaning routine with the Vertical Glass Washing Machine. This innovative technology is changing the game when it comes to keeping your windows spotless and streak-free. Say hello to a hassle-free, efficient way to achieve crystal-clear windows in no time. Read on to discover how this revolutionary machine can transform your window cleaning experience.

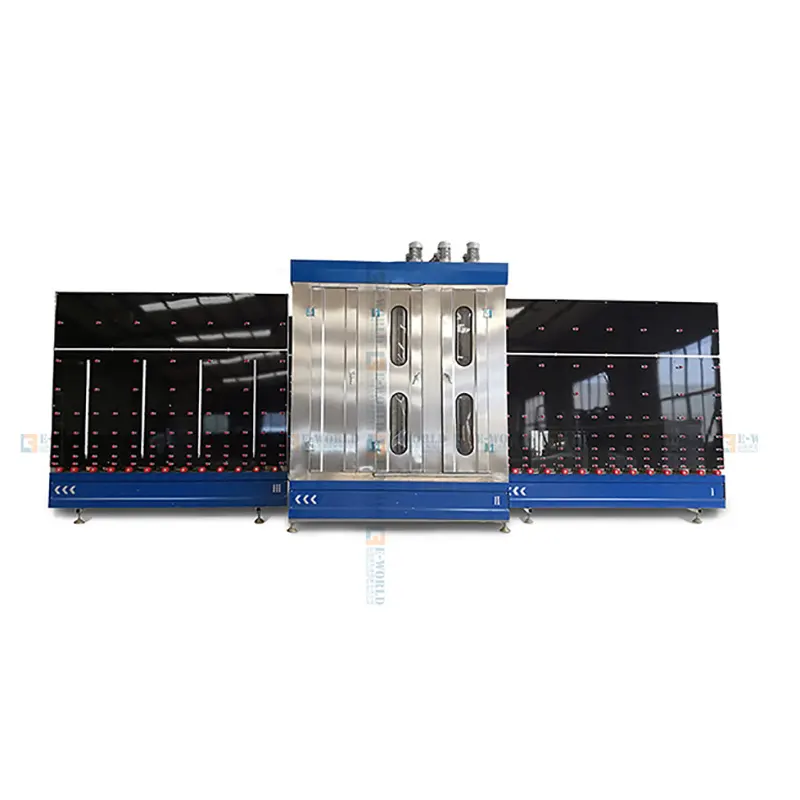

- Introduction to Vertical Glass Washing Machines

Vertical glass washing machines have completely revolutionized the window manufacturing industry in recent years. These machines have drastically improved the efficiency and quality of the glass cleaning process, leading to superior end products and increased customer satisfaction. In this article, we will explore the introduction of vertical glass washing machines, their technological advancements, and their impact on the window manufacturing industry.

The introduction of vertical glass washing machines has brought about a significant shift in the way windows are cleaned and prepared for assembly. Traditionally, window manufacturers used horizontal glass washing machines, which were limited in their capabilities and often resulted in inefficiencies and inconsistencies in the cleaning process. Vertical glass washing machines, on the other hand, are designed to accommodate the specific needs of the window industry, providing a more effective and thorough cleaning process for glass panels.

One of the key technological advancements of vertical glass washing machines is their ability to clean both sides of the glass simultaneously. This dual-sided cleaning feature ensures that the entire surface of the glass is thoroughly cleaned, eliminating the need for additional cleaning processes and reducing the risk of imperfections in the finished product. Furthermore, vertical glass washing machines are equipped with state-of-the-art water filtration systems, which ensure that the glass is washed with clean, purified water, resulting in a streak-free and spotless finish.

Another notable feature of vertical glass washing machines is their ability to accommodate various glass sizes and thicknesses. This flexibility allows window manufacturers to efficiently clean a wide range of glass panels, from standard window sizes to custom-designed architectural glass, without the need for additional equipment or manual adjustments. This versatility not only streamlines the production process but also increases the overall productivity of window manufacturing facilities.

The impact of vertical glass washing machines on the window manufacturing industry cannot be overstated. The efficiency and precision of these machines have led to a significant improvement in the quality of windows produced. The use of vertical glass washing machines has resulted in windows that are free from streaks, smudges, and other imperfections, ultimately enhancing the aesthetic appeal and performance of the final product. In addition, the streamlined cleaning process has reduced overall production time, allowing manufacturers to fulfill orders more quickly and efficiently.

Furthermore, the implementation of vertical glass washing machines has had a positive impact on the overall sustainability of the window manufacturing process. The automated cleaning process and efficient water filtration systems minimize waste and reduce the environmental impact of window production. By using less water and producing less waste, window manufacturers can significantly decrease their carbon footprint while maintaining high-quality standards.

In conclusion, the introduction of vertical glass washing machines has brought about a dramatic transformation in the window manufacturing industry. These machines have revolutionized the way windows are cleaned and prepared for assembly, leading to improved efficiency, superior quality, and increased sustainability. As the demand for high-quality windows continues to rise, vertical glass washing machines will undoubtedly play a crucial role in meeting these demands and shaping the future of window manufacturing.

- Benefits of Using Vertical Glass Washing Machines

When it comes to keeping windows clean and pristine, vertical glass washing machines have revolutionized the way professionals and businesses maintain the appearance of their buildings. These innovative machines offer a range of benefits, from increased productivity to improved safety and overall efficiency.

One of the key advantages of utilizing a vertical glass washing machine is the significant increase in productivity. Traditional methods of window cleaning, such as using ladders or scaffolding, can be time-consuming and labor-intensive. With a vertical glass washing machine, multiple windows can be cleaned simultaneously, reducing the amount of time and effort required to complete the job. This increased efficiency allows professionals to take on more projects and deliver exceptional results within a shorter timeframe.

In addition to enhancing productivity, vertical glass washing machines are also known for their ability to improve safety. Cleaning windows on high-rise buildings or hard-to-reach areas can pose significant risks to workers, often requiring them to use unstable equipment or work at dangerous heights. Vertical glass washing machines eliminate these risks by providing a safe and stable platform for operators to work from. This not only protects the health and well-being of workers but also minimizes the potential for accidents and injuries on the job.

Furthermore, vertical glass washing machines offer superior cleaning performance compared to traditional methods. With advanced technology and specialized cleaning solutions, these machines are able to achieve a level of cleanliness that is unmatched by manual techniques. The precision and consistency provided by vertical glass washing machines ensure that windows are free from streaks, smudges, and other imperfections, resulting in a flawless finish that enhances the overall appearance of the building.

Another benefit of using vertical glass washing machines is the conservation of water and cleaning solutions. These machines are designed to efficiently distribute cleaning agents and water, minimizing waste and reducing environmental impact. By using the precise amount of resources needed to achieve optimal results, vertical glass washing machines contribute to sustainability efforts and promote eco-friendly practices within the industry.

Lastly, vertical glass washing machines offer a cost-effective solution for businesses and professionals. While the initial investment may seem substantial, the long-term savings and return on investment make these machines a worthwhile asset. By streamlining the window cleaning process, reducing the need for extensive labor, and minimizing the risk of accidents and damage, vertical glass washing machines help businesses save time and money in the long run.

In conclusion, the benefits of using vertical glass washing machines are numerous and impactful. From increased productivity and improved safety to superior cleaning performance and cost-effectiveness, these machines have transformed the way windows are maintained and upheld. As the demand for efficient and reliable window cleaning solutions continues to grow, vertical glass washing machines have proven to be an invaluable asset for businesses and professionals alike.

- How Vertical Glass Washing Machines Are Revolutionizing the Window Industry

The window industry is constantly evolving with new technologies and innovations, and the latest game-changer is the vertical glass washing machine. This revolutionary piece of equipment is transforming the way windows are produced, cleaned, and maintained, and is quickly becoming a staple in window manufacturing facilities around the world.

Vertical glass washing machines are a relatively new innovation in the window industry, but they are already making a big impact. Traditional horizontal glass washing machines have been the industry standard for many years, but they have several limitations. For example, they are not well-suited for washing larger, heavier, or more complex shaped glass panels. This is where vertical glass washing machines come in.

One of the main advantages of vertical glass washing machines is their ability to handle a wide range of glass panel sizes and shapes. Due to their vertical design, these machines can accommodate larger and heavier glass panels with ease, making them perfect for manufacturing floor-to-ceiling windows, glass facades, and other architectural glass applications. This versatility is a game-changer for window manufacturers, allowing them to expand their product offerings and take on more complex projects.

In addition to their ability to handle larger and heavier glass panels, vertical glass washing machines also offer improved cleaning capabilities compared to their horizontal counterparts. The vertical orientation of these machines allows for better water and detergent distribution, resulting in a more thorough and efficient cleaning process. This ensures that the glass panels come out spotless and free from any streaks or residues, which is essential for high-quality window production.

Moreover, vertical glass washing machines are also designed with efficiency and automation in mind. These machines are equipped with advanced controls and sensors that allow for precise control over the washing process, leading to reduced water and detergent usage. This not only benefits the environment but also helps manufacturers save on operational costs in the long run.

The implementation of vertical glass washing machines has also had a positive impact on worker safety and ergonomics. Traditional horizontal glass washing machines typically require workers to manually handle and maneuver large and heavy glass panels, which can be physically demanding and pose injury risks. In contrast, vertical glass washing machines feature automated loading and unloading systems, reducing the need for manual handling and minimizing the risk of workplace accidents.

Overall, the introduction of vertical glass washing machines has revolutionized the window industry by providing window manufacturers with a versatile, efficient, and safe solution for producing high-quality glass panels. As these machines continue to gain popularity and become more widely adopted, we can expect to see even more advancements and improvements in window production and design in the years to come. The future of the window industry is looking brighter and clearer than ever before, thanks to the innovation and capabilities of vertical glass washing machines.

- The Future of Vertical Glass Washing Machines

.

The future of vertical glass washing machines is set to revolutionize the window manufacturing industry. With advancements in technology and increasing demand for high-quality, energy-efficient windows, the vertical glass washing machine is poised to become a staple in the production process.

Traditionally, horizontal glass washing machines have been the go-to for cleaning and drying glass panes. However, with the introduction of vertical glass washing machines, manufacturers can now streamline their operations and achieve higher levels of efficiency and productivity.

One of the key benefits of vertical glass washing machines is their ability to clean and dry glass panes in a vertical orientation, eliminating the need for manual handling and reducing the risk of damage to the glass. This innovative design not only saves time and labor but also ensures a consistent and thorough cleaning process, resulting in a higher quality finished product.

Additionally, vertical glass washing machines are equipped with advanced technology that allows for precise control of the cleaning and drying process. This level of precision ensures that each glass pane is thoroughly cleaned and dried, removing any contaminants or residue that may affect the performance or appearance of the final product.

Furthermore, the future of vertical glass washing machines is paved with opportunities for customization and automation. Manufacturers can tailor these machines to their specific needs, whether it be adjusting cleaning parameters for different types of glass or integrating them into a fully automated production line. This level of flexibility and adaptability is crucial for meeting the ever-changing demands of the market.

From an environmental standpoint, vertical glass washing machines also offer significant benefits. By utilizing a closed-loop water recycling system, these machines minimize water consumption and reduce waste, making them a sustainable and eco-friendly choice for window manufacturers.

As the demand for energy-efficient windows continues to rise, the importance of having clean and defect-free glass panes becomes increasingly crucial. Vertical glass washing machines play a pivotal role in achieving this goal, as they ensure that windows meet the highest standards for performance and visual appeal.

In conclusion, the future of vertical glass washing machines is bright and full of potential. With their ability to streamline operations, improve efficiency, and deliver superior results, these machines are set to revolutionize the window manufacturing industry. As technology continues to advance and the need for high-quality, energy-efficient windows grows, vertical glass washing machines will undoubtedly play a vital role in shaping the future of window production.

- Choosing the Right Vertical Glass Washing Machine for Your Business

Revolutionizing Windows: The Vertical Glass Washing Machine - Choosing the Right Vertical Glass Washing Machine for Your Business

In the world of window manufacturing, the vertical glass washing machine has become an indispensable tool for businesses looking to streamline their processes and produce high-quality glass products. With the ability to clean and dry large, vertical glass panes quickly and efficiently, these machines have revolutionized the industry, making it easier for manufacturers to meet the demands of their customers.

When choosing the right vertical glass washing machine for your business, there are several factors to consider, including size, capacity, and features. It's essential to find a machine that can handle the size and quantity of glass panes you work with, while also providing the necessary cleaning and drying capabilities to meet your production needs.

One of the most critical factors to consider when selecting a vertical glass washing machine is the size of the glass panes it can handle. Some machines are designed to clean and dry standard-sized windows, while others are more versatile and can accommodate larger or custom-sized panes. It's crucial to choose a machine that can handle the specific needs of your business, as investing in a machine that is too small or too large for your operations can lead to inefficiencies and increased production costs.

Capacity is another essential consideration when choosing a vertical glass washing machine. The capacity of the machine will determine how many glass panes it can clean and dry at once, affecting the overall efficiency of your production process. Some machines can handle multiple panes simultaneously, while others are designed for smaller-scale operations. Understanding your production needs and the volume of glass panes you work with will help you determine the right capacity for your business.

In addition to size and capacity, it's essential to consider the features of a vertical glass washing machine before making a decision. Some machines offer advanced cleaning and drying capabilities, such as adjustable water pressure, multiple cleaning brushes, and integrated drying systems. These features can improve the quality and efficiency of the cleaning process, leading to higher-quality glass products and increased productivity.

Another important consideration when choosing a vertical glass washing machine is the overall reliability and maintenance requirements of the machine. Investing in a machine that is durable and requires minimal maintenance can save you time and money in the long run, while also minimizing downtime and interruptions to your production process.

Ultimately, choosing the right vertical glass washing machine for your business requires careful consideration of your specific needs and production requirements. By evaluating the size, capacity, features, and maintenance requirements of different machines, you can find a machine that will streamline your production process and help you meet the demands of your customers.

In conclusion, the vertical glass washing machine has revolutionized the window manufacturing industry, providing businesses with the tools they need to clean and dry large, vertical glass panes quickly and efficiently. When choosing the right machine for your business, it's essential to consider factors such as size, capacity, features, and reliability to ensure that you find a machine that meets your specific needs and production requirements.

Conclusion

In conclusion, the vertical glass washing machine has truly revolutionized the way we clean windows. With over 10 years of experience in the industry, we have seen firsthand the impact that this innovative technology has had on our business and the industry as a whole. By automating and streamlining the window washing process, this machine has not only increased efficiency and productivity, but also improved the overall quality of our work. As we continue to embrace new technology and innovation, we are excited to see what the future holds for the window cleaning industry. The vertical glass washing machine has certainly set a new standard for excellence, and we look forward to seeing how it will continue to shape the industry in the years to come.