Advancements In Insulating Glass Technology: The Insulating Glass Machine Revolution

Are you curious about the latest breakthroughs in insulating glass technology? Look no further! In this article, we will delve into the revolutionary advancements in insulating glass machines and how they are transforming the industry. From improved energy efficiency to enhanced durability, the insulating glass machine revolution is paving the way for a new era in glass production. Join us as we explore the cutting-edge innovations that are shaping the future of insulating glass technology.

- The History of Insulating Glass Technology

Insulating glass, also known as double glazing, has become an essential component in modern architectural design. The history of insulating glass technology is a fascinating journey that has seen significant advancements in manufacturing processes, materials, and machinery. In this article, we will explore the evolution of insulating glass technology, with a specific focus on the insulating glass machine revolution.

Insulating glass technology has its roots in the mid-20th century when the need for energy-efficient building materials became increasingly apparent. The idea behind insulating glass is simple: two or more panes of glass are sealed together with a space between them, creating a barrier that reduces heat transfer and improves insulation. However, the process of manufacturing insulating glass was initially labor-intensive and required skilled craftsmanship.

The insulating glass machine revolution began in the late 20th century with the development of automated equipment that could mass-produce insulating glass units with higher precision and efficiency. These machines revolutionized the industry by streamlining the production process and reducing labor costs, making insulating glass more accessible and affordable for a wide range of applications.

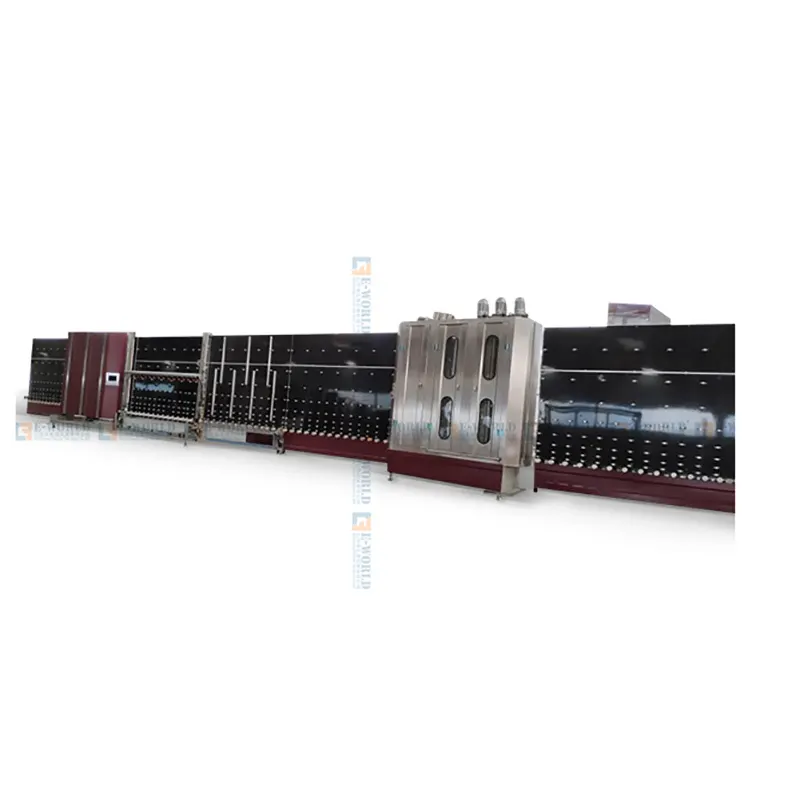

One of the key advancements in insulating glass machine technology was the introduction of fully automated production lines. These systems are capable of cutting, washing, and sealing glass panels with minimal human intervention, significantly increasing output and consistency. The integration of robotics and computerized controls has further improved the speed and accuracy of insulating glass manufacturing, leading to higher quality products and shorter lead times.

Another significant development in insulating glass machine technology is the incorporation of warm-edge spacer systems. Traditionally, insulating glass units were constructed using aluminum spacers, which were highly conductive and led to heat loss at the edges of the glass. Warm-edge spacers, made from low-conductivity materials such as stainless steel or thermoplastic, have become standard in modern insulating glass production, improving thermal performance and reducing condensation.

Furthermore, advancements in sealant application technology have played a crucial role in the insulating glass machine revolution. Modern equipment can precisely apply a variety of sealants, including silicone, polyurethane, and polysulfide, ensuring a durable and airtight seal for insulating glass units. These advancements have significantly enhanced the longevity and performance of insulating glass in various environmental conditions.

In recent years, insulating glass machine manufacturers have focused on integrating sustainability and energy efficiency into their equipment. New innovations such as energy-efficient heating systems, automatic glass thickness detection, and real-time production monitoring have further improved the overall efficiency of insulating glass manufacturing processes, reducing waste and energy consumption.

In conclusion, the history of insulating glass technology is one of continuous innovation and improvement, driven by the insulating glass machine revolution. The advancements in automated production lines, warm-edge spacer systems, sealant application technology, and sustainable manufacturing practices have transformed the industry, making insulating glass a highly efficient and cost-effective solution for modern buildings. As the demand for energy-efficient building materials continues to grow, the insulating glass machine revolution will undoubtedly play a pivotal role in shaping the future of insulating glass technology.

- The Evolution of Insulating Glass Machines

Advancements in Insulating Glass Technology: The Evolution of Insulating Glass Machines

Insulating glass technology has come a long way in recent years, with significant advancements in insulating glass machines leading the charge. The revolution in insulating glass machines has greatly improved the efficiency, quality, and production capabilities of insulating glass units (IGUs), making them an increasingly popular choice for modern buildings.

One of the key factors driving the evolution of insulating glass machines is the demand for energy-efficient and sustainable building materials. Insulating glass units, which consist of two or more panes of glass separated by a sealed air space, are highly effective at reducing heat transfer and improving thermal insulation in buildings. As a result, the demand for IGUs has soared, leading to a greater need for advanced insulating glass machines that can produce high-quality IGUs at a faster rate.

The evolution of insulating glass machines can be traced back to the development of new manufacturing processes and technologies. In the past, insulating glass units were typically manufactured manually, which was both time-consuming and prone to human error. Today, however, insulating glass machines are equipped with advanced automation and robotics, allowing for precise and efficient production of IGUs. These machines are capable of handling various types of glass, including low-E glass, tempered glass, laminated glass, and even curved glass, making them highly versatile and adaptable to different construction requirements.

Furthermore, the evolution of insulating glass machines has also led to improvements in the quality and durability of IGUs. Advanced sealing technologies and insulating gas filling systems have significantly reduced the risk of moisture infiltration and gas leakage in IGUs, leading to longer lifespans and better performance. In addition, the use of advanced spacer technologies, such as warm edge spacers, has improved the thermal efficiency of IGUs, further enhancing their energy-saving properties.

Another significant advancement in insulating glass machines is the integration of digital technologies and smart manufacturing solutions. Modern insulating glass machines are equipped with computerized control systems and data management tools, allowing for real-time monitoring and optimization of the production process. This enables manufacturers to achieve higher productivity, reduce material waste, and maintain consistent product quality.

In conclusion, the evolution of insulating glass machines has played a pivotal role in the advancement of insulating glass technology. With their enhanced efficiency, production capabilities, and quality, insulating glass machines have revolutionized the manufacturing process of IGUs, making them an indispensable component of modern building construction. As the demand for energy-efficient and sustainable building materials continues to grow, the evolution of insulating glass machines will undoubtedly remain a key driving force in the development of insulating glass technology.

- Key Advancements in Insulating Glass Technology

Insulating glass technology has seen significant advancements in recent years, thanks to the insulating glass machine revolution. These machines have revolutionized the way insulating glass is manufactured, leading to key advancements in the industry. The insulating glass machine revolution has paved the way for improved energy efficiency, increased durability, and enhanced performance of insulating glass units.

One of the key advancements in insulating glass technology is the use of automated insulating glass machines. These machines have greatly improved the efficiency and accuracy of the manufacturing process, leading to higher quality insulating glass units. Automated machines can handle a variety of tasks, such as washing, drying, and sealing, with minimal human intervention, leading to consistent and precise results.

Furthermore, insulating glass machines have also evolved to incorporate advanced sealing technologies. The use of hot melt sealants and flexible spacer systems has significantly improved the durability and longevity of insulating glass units. These advanced sealing technologies help to prevent moisture ingress, which can lead to fogging and reduced thermal performance. As a result, insulating glass units manufactured using these technologies are more durable and have a longer lifespan.

Another important advancement in insulating glass technology is the integration of gas filling machines. These machines allow insulating glass units to be filled with inert gases, such as argon or krypton, to improve their thermal performance. Gas filling machines ensure that the insulating glass units are filled with the precise amount of gas, leading to enhanced energy efficiency and improved insulation properties. This advancement has been crucial in meeting the increasing demand for energy-efficient building materials.

Additionally, insulating glass machines have also introduced innovations in glass treatment and processing. These machines are capable of handling a variety of glass types, including low-emissivity coatings and laminated glass. This allows for the production of insulating glass units with enhanced solar control and safety features. Furthermore, the integration of smart glass technologies, such as electrochromic and thermochromic coatings, is also made possible by insulating glass machines, offering advanced functionality and control over light transmission and solar heat gain.

The insulating glass machine revolution has not only advanced the manufacturing process but has also contributed to the development of sustainable insulating glass products. The use of automated machines reduces material waste and energy consumption, leading to a more eco-friendly production process. Furthermore, the advancements in insulating glass technology have enabled the development of high-performance insulating glass units that contribute to the overall energy efficiency of buildings, reducing the environmental impact of heating and cooling systems.

In conclusion, the insulating glass machine revolution has brought about key advancements in insulating glass technology, leading to improved energy efficiency, increased durability, and enhanced performance of insulating glass units. The integration of automated machines, advanced sealing technologies, gas filling capabilities, and innovations in glass treatment and processing has revolutionized the way insulating glass is manufactured. These advancements have not only improved the quality of insulating glass products but have also contributed to the development of sustainable and energy-efficient building materials.

- The Impact of the Insulating Glass Machine Revolution

The insulating glass machine revolution has had a significant impact on the advancements in insulating glass technology. This revolution has transformed the way insulating glass is produced, making the process more efficient, precise, and cost-effective. In this article, we will explore the technological advancements that have been brought about by the insulating glass machine revolution, and the effects it has had on the industry.

One of the key advancements brought about by the insulating glass machine revolution is the increased automation of the production process. Insulating glass machines are now equipped with advanced robotic systems that can carry out tasks such as glass cutting, edge grinding, and spacer application with a level of precision and speed that was previously unattainable. This has not only increased the efficiency of the production process but has also minimized the margin of error, resulting in higher quality insulating glass products.

Furthermore, the insulating glass machine revolution has also led to the development of new and innovative techniques for producing insulating glass. For example, some of the latest insulating glass machines are capable of producing triple and even quadruple glazed units, providing superior levels of thermal and acoustic insulation. These machines also have the ability to produce complex shapes and sizes of insulating glass, expanding the possibilities for architects and designers.

In addition to advancements in production techniques, the insulating glass machine revolution has also had a significant impact on the environmental sustainability of insulating glass production. The latest machines are designed to minimize energy consumption and waste, making them more environmentally friendly than older models. The use of automated systems also reduces the need for manual labor, leading to a decrease in the industry's carbon footprint.

The insulating glass machine revolution has not only improved the production process but has also had a positive effect on the overall quality of insulating glass products. The precision and accuracy of the latest machines have led to insulating glass units that have higher levels of structural integrity and longevity. These advancements have made insulating glass a preferred choice for architects and builders, as it offers both aesthetic appeal and practical benefits.

Furthermore, the insulating glass machine revolution has also had a significant impact on the cost-effectiveness of insulating glass production. The increased efficiency and precision of the latest machines have led to a reduction in production costs, making insulating glass more affordable for both manufacturers and consumers. This has resulted in an increased demand for insulating glass products, further driving the growth of the industry.

In conclusion, the insulating glass machine revolution has been a game-changer for the insulating glass industry. The technological advancements brought about by this revolution have transformed the way insulating glass is produced, leading to increased efficiency, precision, and cost-effectiveness. These advancements have not only improved the quality and sustainability of insulating glass products but have also expanded the possibilities for architects and designers. As the industry continues to embrace the latest innovations, it is clear that the insulating glass machine revolution will continue to shape the future of insulating glass technology.

- Future Innovations in Insulating Glass Technology

Insulating glass technology has come a long way in the last few decades, with constant advancements and innovations making insulating glass more efficient and durable. The latest revolution in insulating glass technology is the insulating glass machine, which is set to further improve the production process and the performance of insulating glass units.

One of the key future innovations in insulating glass technology is the introduction of automated insulating glass machines. These cutting-edge machines are designed to streamline the production process, reducing human error and increasing efficiency. They are equipped with advanced robotics and computerized controls, allowing for precise assembly of insulating glass units. This not only ensures higher quality products, but also reduces production time and costs.

Another important development in insulating glass technology is the use of smart technology in insulating glass machines. Smart insulating glass machines are integrated with sensors and data analytics, enabling real-time monitoring of the production process. This not only helps in identifying and rectifying any issues in the production line, but also allows for predictive maintenance, ensuring that the machines operate at optimum efficiency.

Furthermore, the future of insulating glass machines also involves the implementation of energy-efficient and eco-friendly technologies. Insulating glass units are already known for their thermal insulation properties, and with the advancements in insulating glass machine technology, the production process is set to become even more energy-efficient. This includes the use of advanced materials and coatings, as well as the adoption of sustainable manufacturing processes to reduce environmental impact.

Moreover, the future of insulating glass machines also involves the use of advanced technologies such as 3D printing. 3D printed insulating glass units are set to revolutionize the industry, offering precise and intricate designs that were previously impossible to achieve. This not only opens up a new realm of possibilities in architectural design, but also allows for customization according to specific requirements.

In addition to these technological advancements, the future of insulating glass machines also involves the integration of automation and robotics. Automated insulating glass machines are set to revolutionize the production process, reducing human intervention and increasing efficiency. These machines are equipped with advanced robotics and automated controls, allowing for precise and accurate assembly of insulating glass units.

In conclusion, the future of insulating glass technology is extremely promising, with insulating glass machines at the forefront of innovation. The incorporation of smart technology, automation, energy-efficient solutions, and advanced manufacturing processes is set to revolutionize the production of insulating glass units, making them more durable, efficient, and eco-friendly than ever before. As the industry continues to evolve, insulating glass machines will play a crucial role in shaping the future of insulating glass technology.

Conclusion

In conclusion, the advancements in insulating glass technology have brought about a revolution in the industry. With the introduction of insulating glass machines, companies like ours, with 10 years of experience, have been able to greatly improve the efficiency and quality of our products. This technology has allowed us to meet the growing demands of our customers and stay competitive in the market. As we look towards the future, we are excited to see how further advancements in insulating glass technology will continue to revolutionize the industry and provide even better solutions for our customers.